About Inventory Monitoring, Automation & Control

Inventory Monitoring, Automation & Control :

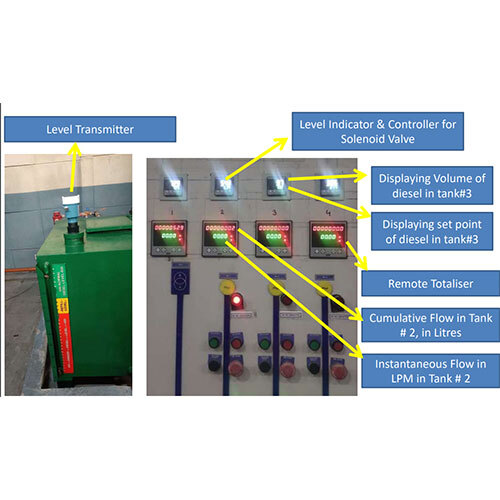

It consists of a combination of one or more of the following :

1. Level / Volume Sensor

2. Level / Volume Indicator

3. Flow sensors

4. Solenoid Valves

5. Wired / Wireless Communication / Data Transmission set up

6. On site power generation / backup

7. Cloud / Server etc.

Comprehensive Automation for Diverse MediaIdeal for monitoring liquid or solid inventory, this system supports capacitive and ultrasonic sensors for accurate, real-time measurements. It manages flow rates from 0 to 5000 LPH, tank capacities up to 50,000 liters, and operates over a wide pressure (up to 10 bar) and temperature range (-10C to +60C). It's engineered for high reliability and flexibility in diverse industrial environments.

Effortless Integration and ConnectivityWith MODBUS RTU/TCP support, analog & digital outputs, relay alarm contacts, as well as Ethernet and RS485 connectivity, this unit integrates seamlessly into existing SCADA, PLC, or building management systems. Its wall or panel mount options, customizable logging, and LED digital display make deployment and daily monitoring straightforward and efficient.

FAQ's of Inventory Monitoring, Automation & Control:

Q: How is the inventory monitoring system installed and mounted?

A: The system is designed for flexible installation, supporting both wall and panel mounting. Its enclosure dimensions (320mm x 260mm x 100mm) facilitate easy placement in control rooms or industrial spaces, ensuring robust protection and convenient access for maintenance.

Q: What process does the system use for automatic and manual calibration?

A: The device supports both automatic and manual calibration modes. For automatic calibration, simply initiate the calibration process via the display interface, and the unit will self-adjust. Manual calibration allows users to fine-tune sensor readings for specific tanks or media, ensuring optimal accuracy for each application.

Q: When should I use the alarm output functionality, and how does it work?

A: The relay alarm output (NO/NC contact) is designed to trigger when user-defined inventory levels are reached, such as overfill or low inventory thresholds. Alarms are configured through the system interface and provide immediate notification for prompt corrective action.

Q: Where can this system be utilized and what types of application media are supported?

A: This monitoring system is suitable for industrial facilities across India handling liquids and solids, including water, chemicals, powders, and grains. Its capacitive and ultrasonic sensors enable accurate measurement in a wide array of applications, making it versatile for process industries, warehouses, and commercial storage.

Q: What are the benefits of customizable data logging intervals?

A: Customizable data logging intervals (ranging from 1 to 60 minutes) empower users to balance detailed inventory trend tracking with storage efficiency. This flexibility helps optimize reporting, monitor usage patterns, and meet specific operational needs without overloading storage or missing critical events.

Q: How does the system ensure high accuracy and reliability in monitoring?

A: With an accuracy of 0.5%, IP65 ingress protection, and materials like mild steel, the unit is engineered for harsh industrial environments. The system seamlessly integrates analog (4-20mA) and digital outputs for real-time monitoring and control, ensuring dependable performance even in demanding applications.