About Plant & Machinery for Biogas

CBG Plant & Machinery:

Follwing instruments and machinery are available for CBG, in addition to overall turnkey solutions:

1. Gas & Liquid - Volumetric & Mass Flow meters

2. Level Sensors

3. Pressure Sensors

4. Pumps, Agitators

5. Solid Liquid Separators

6. Gas based power generators, Analyser etc.

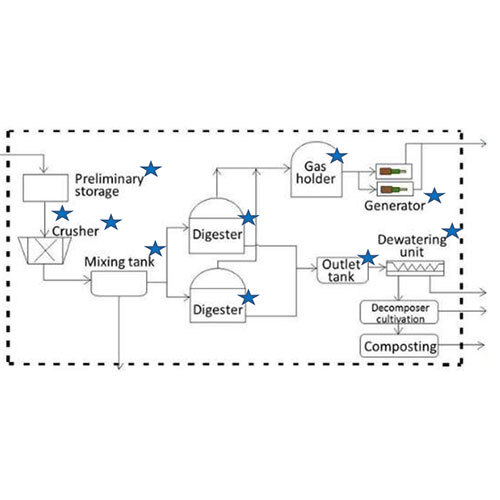

Versatile Digesters and Feed OptionsOur biogas machinery accommodates a wide variety of feedstocks including cow dung, poultry litter, and general organic waste. With flexible digester types such as Fixed Dome, Floating Drum, or Balloon Types, clients can choose the most effective system for their specific site and input materials. This versatility ensures maximum biogas yield and efficient operation in both rural and urban environments.

High Efficiency with Low MaintenanceEngineered for energy efficiency, our systems operate with minimal power consumption and offer simple, low-maintenance routines. Features like corrosion-resistant materials and weatherproof construction enable trouble-free indoor or outdoor setup. The mechanical or hydraulic mixers, along with automated or manual slurry discharge, contribute to operational simplicity and reliability.

Comprehensive Automation and Accurate MonitoringBenefit from semi-automatic or fully automatic operations, including compatibility with SCADA or PLC systems. Our biogas plants provide high-accuracy gas production measurement with digital or analog displays. Adjust and customize settings, measurement range (10-1000 m3), and flow rates to best match your requirements. All critical process conditions are monitored by advanced sensors, ensuring optimal performance and safety.

FAQ's of Plant & Machinery for Biogas:

Q: How is the biogas plant installed and what location is best?

A: The biogas plant can be installed both indoors and outdoors, thanks to its weatherproof and corrosion-resistant design. It is ideal to set up the plant in an area with good accessibility for feedstock supply and slurry discharge, as well as proximity to where the biogas will be used, such as kitchens, generators, or industrial applications.

Q: What types of raw input can be used in this biogas system?

A: Our biogas plants accept diverse organic inputs, including cow dung, poultry litter, and general organic waste. This flexibility allows for optimal biogas generation from various agricultural, household, or industrial waste sources while reducing environmental footprint.

Q: What is the typical retention time, and can it be adjusted?

A: The biogas plant is designed for adjustable retention times between 15 and 40 days. This setting can be tailored based on the type and quantity of feedstock to ensure efficient digestion and maximize methane purity, ensuring a consistent and reliable output.

Q: How is the produced biogas measured and monitored?

A: Our systems feature high-accuracy measurement with either digital or analog displays, providing real-time data on gas production. Sensors monitor variables such as gas flow, level, pressure, and temperature, ensuring that the production process is safe, reliable, and optimized for your requirements.

Q: What maintenance is required for this biogas plant?

A: Designed for easy maintenance, the plant utilizes corrosion-resistant materials and efficient mechanical or hydraulic mixers. Periodic checks on slurry discharge, seals, and safety valves are recommended, but overall maintenance is minimal, ensuring long-term, hassle-free operation.

Q: What are the main benefits of using this automated biogas system?

A: Key benefits include efficient conversion of organic waste into biogas and fertilizer (bio-slurry), low operational costs, minimal maintenance, high methane purity (60-70%), energy efficiency, and adaptable capacity. Automation and advanced monitoring reduce manual labor while enhancing plant safety and productivity.

Q: Can the plant be customized for different biogas applications and capacities?

A: Yes, our biogas equipment offers customizable measurement ranges, tank diameters, and flow rates, supporting daily capacities from 1 m3 to 1000 m3. It can be seamlessly integrated with manual, SCADA, or PLC connectivity to suit a variety of residential, commercial, or industrial functions.